Artificial Intelligence (AI) has been a game-changer across industries, but one of the most promising developments in recent years is the rise of Agentic AI. Unlike traditional AI systems that follow pre-programmed instructions, Agentic AI is designed to act with autonomy, make decisions, and adapt dynamically to changing conditions—qualities that make it particularly valuable in manufacturing.

In this article, we’ll explore how Agentic AI is transforming manufacturing, its real-world applications, benefits, challenges, and what the future holds for smart factories.

What is Agentic AI?

Agentic AI refers to AI systems that go beyond passive data analysis and recommendations. Instead, they function as intelligent agents that:

- Observe and understand environments.

- Make independent decisions.

- Collaborate with humans and other machines.

- Learn and adapt in real-time.

This is not simply about automation—it’s about creating AI systems that can take initiative, optimize processes, and manage operations with minimal human intervention.

Why Manufacturing Needs Agentic AI

Manufacturing is one of the most complex and dynamic industries in the world. It requires:

- Managing supply chains.

- Optimizing production lines.

- Reducing downtime and defects.

- Balancing demand forecasting and inventory.

- Ensuring workplace safety and compliance.

Traditional automation and AI systems have improved efficiency, but they remain reactive. Agentic AI introduces proactive intelligence, where systems can anticipate issues and make decisions autonomously.

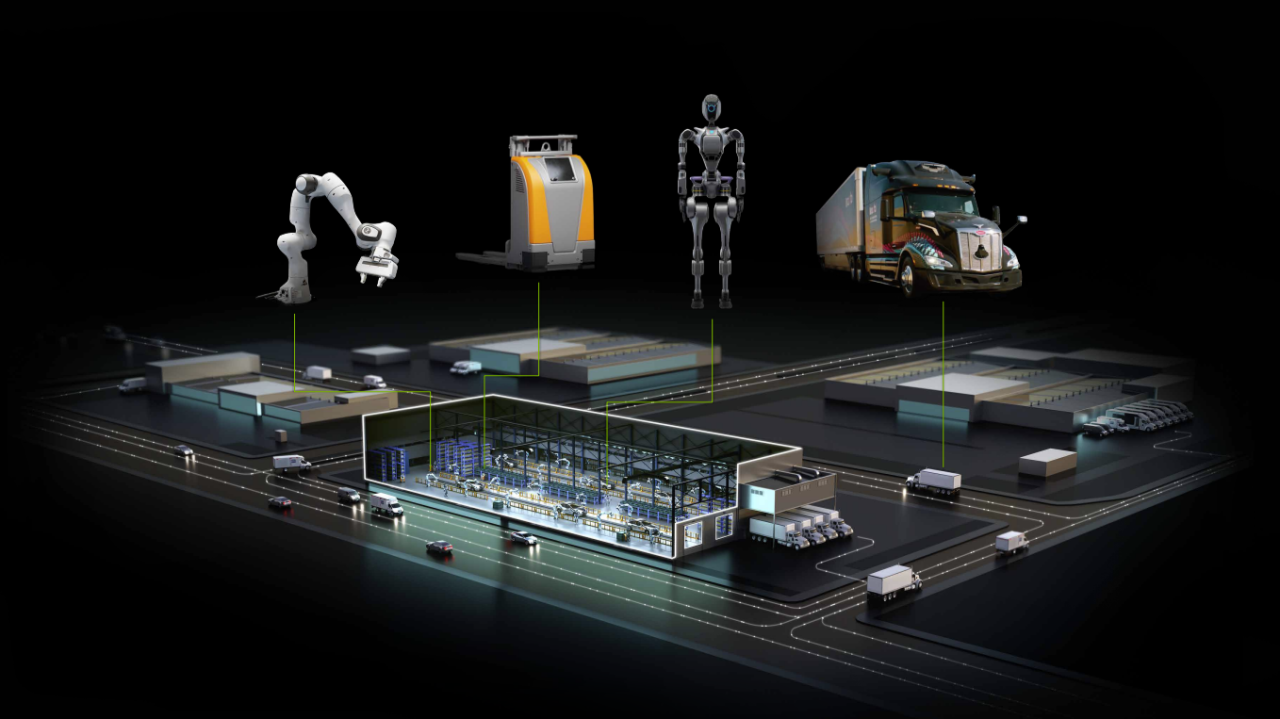

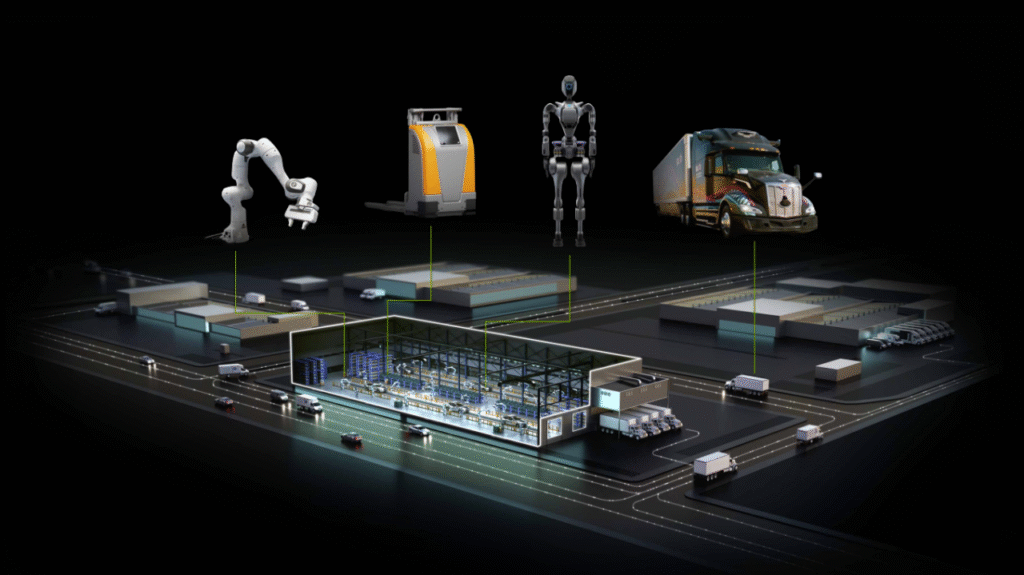

Applications of Agentic AI in Manufacturing

1. Smart Supply Chain Management

Agentic AI can monitor global supply chain disruptions, evaluate alternatives, and automatically adjust procurement strategies.

- Example: If a raw material supplier faces delays, the AI agent can re-route orders to an alternative vendor without waiting for human intervention.

2. Predictive Maintenance & Self-Healing Machines

Traditional predictive maintenance relies on data to alert engineers. With Agentic AI, machines can:

- Predict failures.

- Schedule their own maintenance.

- Reconfigure operations to minimize downtime.

This turns factories into self-managing ecosystems.

3. Autonomous Production Line Optimization

Agentic AI agents can dynamically adjust machine speeds, allocate tasks, and balance workloads.

- Example: If a robot malfunctions, the AI can reassign tasks to other robots while alerting maintenance teams—without halting the entire line.

4. Quality Control & Defect Detection

Using computer vision and reinforcement learning, AI agents can detect defects in real-time and autonomously remove faulty items or adjust production settings to minimize errors.

5. Workforce Collaboration & Safety

Agentic AI systems can act as co-bots (collaborative robots), ensuring worker safety.

- Detecting hazards in real-time.

- Re-routing workers away from dangerous zones.

- Assisting with heavy lifting or precision tasks.

6. Energy Optimization & Sustainability

Agentic AI can monitor energy usage and autonomously reduce waste.

- Adjusting machine usage to off-peak hours.

- Dynamically shutting down idle systems.

- Optimizing heating, cooling, and resource consumption.

This contributes directly to green manufacturing goals.

Real-World Examples of Agentic AI in Manufacturing

- Siemens is integrating AI agents in its smart factories to monitor and optimize industrial processes.

- BMW uses AI-driven robots that work alongside humans to improve precision and safety.

- Foxconn (Apple’s major supplier) has begun experimenting with AI agents for predictive maintenance and defect detection.

- Tesla’s Gigafactories leverage autonomous AI systems for scaling EV battery production efficiently.

Benefits of Agentic AI in Manufacturing

- Increased Efficiency – Autonomous decisions minimize delays.

- Reduced Downtime – Machines predict and fix issues before breakdowns.

- Cost Savings – Optimized operations reduce energy, labor, and material costs.

- Improved Quality – AI agents ensure consistent monitoring.

- Agility & Resilience – Factories can adapt quickly to supply chain shocks.

- Enhanced Safety – AI co-bots protect workers from risks.

- Sustainability – Smarter resource management reduces carbon footprint.

Challenges of Implementing Agentic AI

While the potential is massive, manufacturers face challenges such as:

- High Initial Investment – Smart AI-driven systems require significant capital.

- Integration Complexity – Merging AI with legacy systems is difficult.

- Data Privacy & Security Risks – Autonomous systems may be vulnerable to cyber threats.

- Workforce Training – Employees need new skills to collaborate with AI.

- Ethical Concerns – Autonomous decision-making must align with safety and compliance standards.

Future of Manufacturing with Agentic AI

The future of Agentic AI in manufacturing points toward Industry 5.0, where humans and autonomous AI agents work hand-in-hand. Some trends include:

- AI-Driven Digital Twins – Virtual replicas of factories that AI agents use to test and optimize processes.

- Hyper-Autonomous Factories – Plants that run 24/7 with minimal human supervision.

- Global Collaboration – AI agents managing cross-border supply chains seamlessly.

- Personalized Manufacturing – On-demand, customized products produced efficiently.

- AI-Governed Sustainability – Factories where AI ensures carbon neutrality.

Final Thoughts

Agentic AI is not just an upgrade to existing automation—it represents a paradigm shift in how manufacturing operates. By giving AI the ability to act autonomously, manufacturers can achieve new levels of efficiency, resilience, and innovation.

Factories of the future won’t just be smart—they’ll be self-governing ecosystems where humans and AI collaborate to create safer, greener, and more efficient production systems.

The rise of Agentic AI marks the beginning of truly intelligent manufacturing, and those who adopt it early will lead the next industrial revolution.